Soiling and weather events are real concerns when it comes to solar systems producing the energy (and financial returns) you expect. But the reality is more severe operational issues are at fault when it comes to your DG solar system’s lack of production.

Thanks to Omnidian’s technology, we’ve identified the most common issues top power producers face that can kill your production and revenue flow.

We set our machine learning algorithm loose on over 380,000 years’ worth of asset data, and our team of solar experts were able to pinpoint the top four operational issues that routinely lead to underperformance across the across the thousands of commercial assets under our management:

1. Inverter Issues

Ask any reputable solar monitoring or technical asset management professional and they will tell you the majority of issues they encounter are inverter-related. Whether string, central, or micro, inverters are often the first piece of equipment to blame when an alert appears or underperformance is detected.

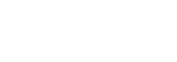

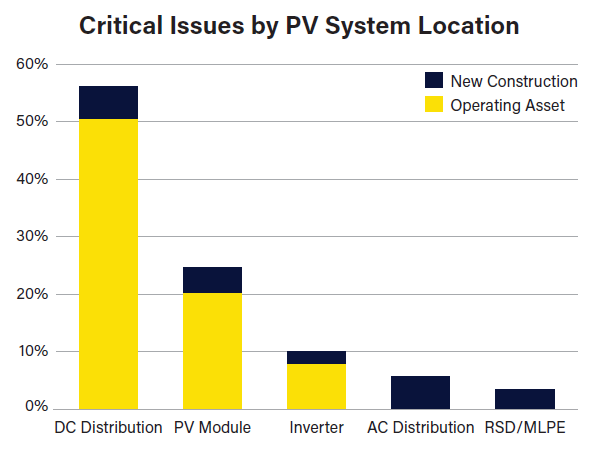

As a central point of a PV system, inverters proportionally have a high chance of seeing faults or failures. HelioVolta, an Omnidian partner, found in its SolarGrade PV Health Report that inverters were consistently one of the top three locations responsible for all levels of safety issues (from critical to negligible) across new and operational commercial systems.

Some typical inverter issues include:

- Improper installation

- Offline communication

- Aging or defective components

- Lack of grid connection

- Wiring problems (more on this in a bit)

Additionally, certain brands of solar inverters have recently been found to have security flaws that could lead to hacking, which could render their connected systems non-operational and lead to unexpected downtime.

While this manufacturing issue can’t be addressed with solar maintenance services (except by swapping inverters), it points to the need for using secure, quality parts across solar portfolios to ensure continued, reliable performance, and for employing a powerful predictive maintenance tool.

2. Wiring Issues

Despite the prevalence of inverter alerts, that hardware isn’t always the root cause of solar performance issues. In fact, wiring, cables, and connectors are often responsible for tripping inverters and causing many site issues.

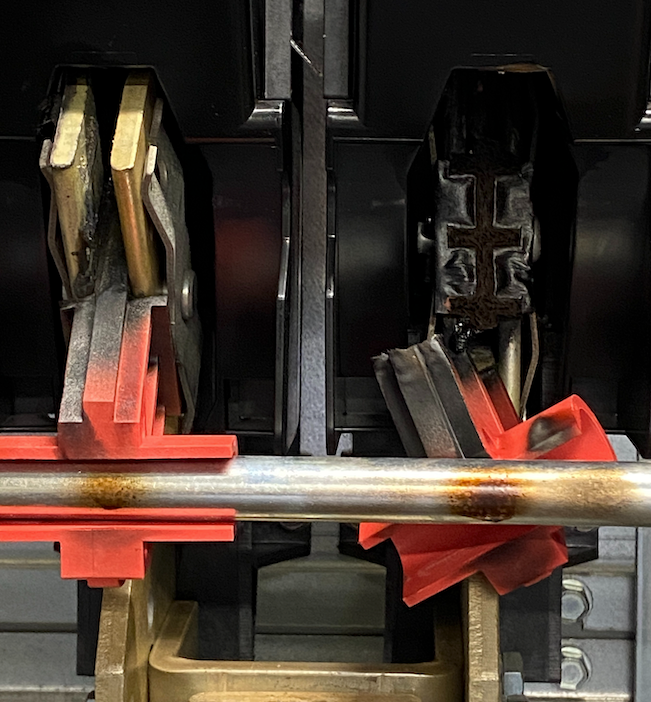

Service technicians in Omnidian’s partner network routinely encounter wiring concerns during preventive maintenance inspections. Todd Michel, Omnidian’s Manager of Technical Operations, said some recent discoveries were related to improper crimps.

“Crimps are durable connections between a wire and connector, and are made with a specialized tool that squeezes around the wire, but we’ve seen many instances where the tool was used incorrectly,” he said. “These crimped lugs were made improperly, creating a bad connection inside, causing the heat and subsequent discoloration visible on the red label below the crimp. This could’ve led to a much larger problem, including a fire, if left unchecked.”

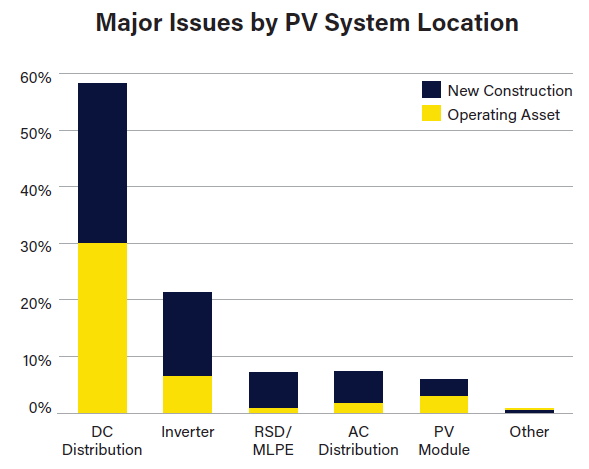

Incorrect wiring practices have long haunted the solar industry, and these issues can cause major problems, including fires (aka thermal events). HelioVolta’s report also discovered that 80% of inspected commercial projects had issues related to wiring, and 83% had connector-related issues.

HelioVolta has since released guidelines on best practices for wire management, but until these practices become standardized industry-wide, expect to see wiring issues affect the performance of your solar assets.

3. BoS-Level Issues

Other equipment at commercial sites can also be the root cause of solar performance interruptions. Referred to as Balance of System (or “BOS”), this equipment includes parts like disconnects, breakers, or conduits.

Omnidian recently orchestrated an emergency service call for one of our large retail clients when a smoking electrical panel was discovered at one of their stores. The Omnidian team was able to get solar technicians on-site within an hour to investigate.

“An employee had turned off the main solar AC disconnect, and the plastic was melting when the disconnect handle was opened,” explains Todd. “The issue required a utility outage / store shutdown to address, but luckily we caught it before it got worse and possibly started a thermal event.”

Todd also notes, “Finding this issue prompted us to do a fleetwide inspection of similar disconnects, which ended up being a vital intervention for our clients as we found others that needed replacing, as well.”

4. Module-Level Issues

While one of the least common places for an issue to arise, module problems can have a direct impact on your system’s production, and if not caught early, can require serious dollars to fix.

Panels can present a host of reliability issues. When the Renewable Energy Test Center released its 2024 PV Module Index Report, only 8% of models met the Center’s top-performing standards for reliability, quality, and performance. And 20% of modules tested by Kiwa-PVEL experienced at least one failure during mechanical load testing.

Microcracks, for example, were found in over 70% of tested modules in one study by Clean Energy Associates. As they increase in size and scale, these breaks can decrease solar performance and energy output, resulting in thousands of dollars of lost revenue and even complete module replacement.

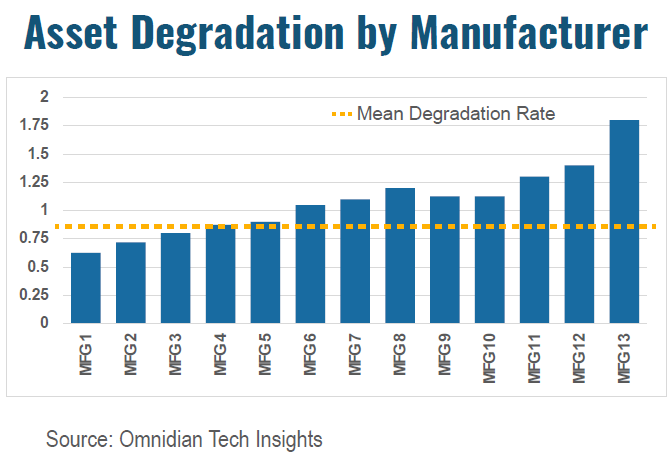

Additionally, like any piece of equipment, modules are subject to degradation over time, with some manufacturers presenting more rapid rates of decline than others.

With access to data from more than 200,000 residential and commercial assets across the U.S., Omnidian has been able to identify and measure differences in asset degradation rates, anonymized by manufacturer. When there’s a significant variation, our team can more accurately diagnose underperforming assets, as well as set more accurate estimates for projected long-term returns from assets.

Optimize Solar Performance with Remote Monitoring and Issue Identification

What steps can you take to mitigate some of these issues and reduce their impact on the solar performance of your commercial systems?

Omnidian’s proactive solar monitoring, remote issue IDing, and operations & maintenance services can help by:

- Diagnosing different alerts and codes. There’s no standardized system of coding or alerting across various parts of a solar installation, which makes it difficult to accurately determine the root cause of issues. Our system can detect and diagnose what different alerts and codes mean across a variety of installed equipment.

- Determining the root cause of alerts. Reduce your truck rolls by determining the actual issue at hand. We can pinpoint if an inverter is at fault, or if there’s an underlying issue that requires technician services, like wiring that needs to be replaced.

- Getting technicians on-site quickly and only when necessary. Our field service network partners are available in 48 states, as well as D.C. and Puerto Rico. When our system determines you need a truck roll, a team of local technicians is ready to help.

- Gaining a complete picture of your equipment’s performance. Our technology is driven by machine learning that helps you understand elements affecting long-term solar performance, such as weather, panel degradation, and more.

Solar performance issues are an unfortunate reality today, but Omnidian is dedicated to proactively solving problems for our clients to ensure long-term asset performance, and consistent return on investment.